What is perfo?

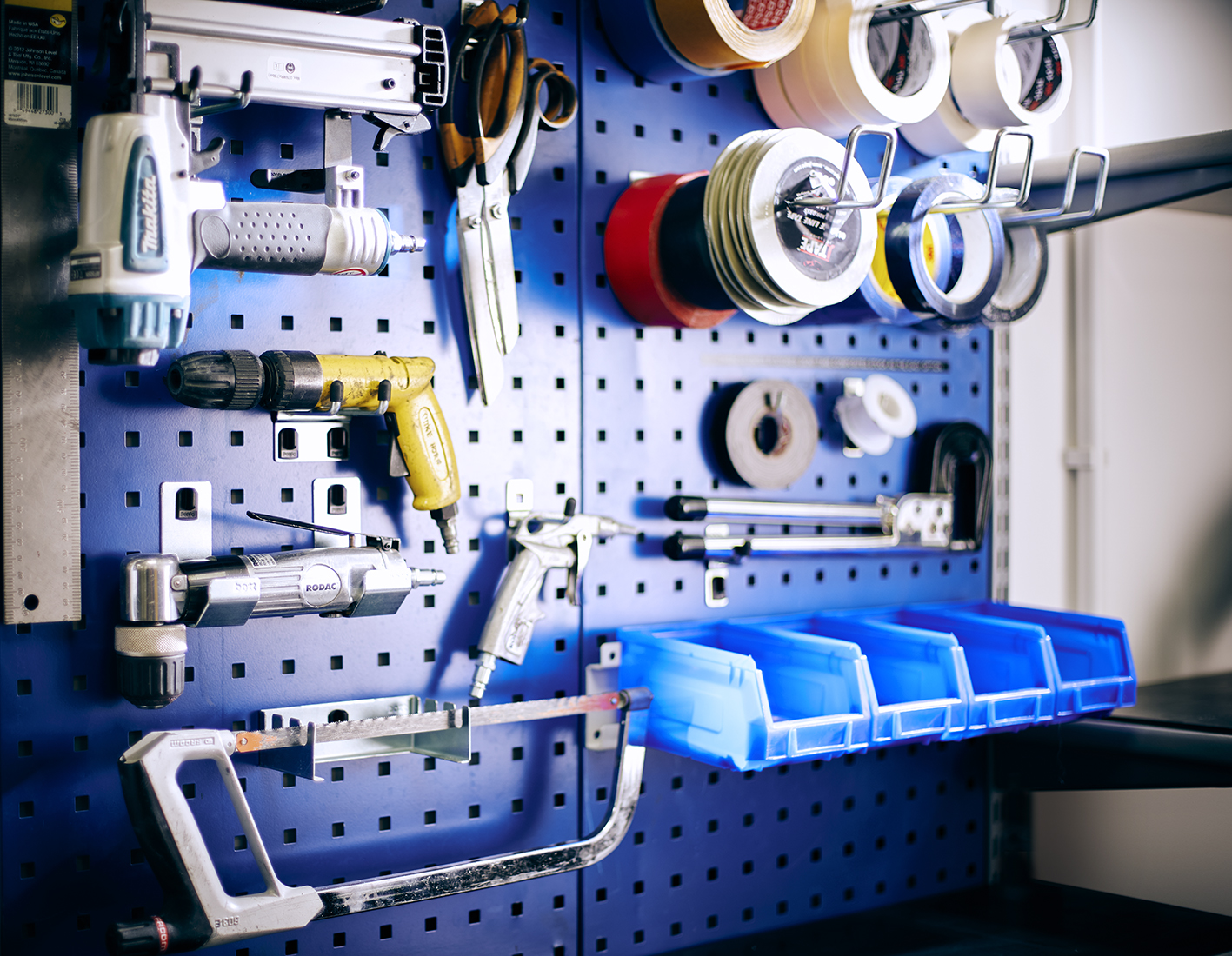

These steel panels are the foundation of small part storage, increasing space, productivity and efficiency in the workplace. Versatile and adaptable, perfo can be integrated into our workspace storage and van racking solutions, with a variety of accessories available for optimised tool storage that suits your individual requirements.

The efficient system is our flexible solution for both cubio and verso; available as wall panels, free-standing and mobile products in perfo, louvre or combi style. Whether you’re on the road or in the workshop, perfo is a comprehensive product that protects, organises and securely stores your tools.

With 5S and LEAN process management being key to optimising operations, our perfo storage system is the perfect tool to minimise disruption in workflows. The perfo panel helps to maintain cleanliness, organisation and order within any work environment to ensure focus remains on best practice and streamlined processes.

The Lockpanel Company Ltd

The Lockpanel Company Ltd

In 1973, The Lockpanel Company Ltd was started in Leicestershire, before relocating to Cornwall a couple of years later. The name perfo is an abbreviation of the term perforated, as the panels use a pattern of equally spaced square holes. The principle of the perfo system has not changed from the original and the panels made today look virtually identical to the first design. There are however slight differences- the squares have been reduced from 10mm to 9.2mm and the material thickness is slightly thinner today.

The original system

The original system

The bott perfo pattern pitch is 38.1mm and the panel width of 457mm, this is based on the imperial system when the measurements were 1.5 inches by 18 inches. The panel lengths which are roughly 0.5, 1.0, 1.5 and 2.0 metres, derived from the perfo pattern, so it continues when panels are placed next to each other.

Part of perfo panel’s success is that it is a simple and versatile product that utilises space, with an extensive range of bott perfo accessories. Easily repositioned and configured in any pattern, perfo hooks & perfolocks are used to hold the tools securely in place and can be adapted to suit personal preference. The perfo system was gradually incorporated into other products and is now used throughout our ergonomic workplace storage and vehicle ranges across The Bott Group.

perfo over the years

perfo over the years

The panels were originally painted with wet spray paint, this then changed to powder paint which we still use today. The hooks and small sheet metal accessories were and still are zinc plated to prevent them from rusting up, this process was done on site up until recently. For a number of years, panels were screen-printed with specific tool shapes to create shadow boards for car manufacturers, this has since been replaced by plastic sheets.

Over the years, the perfo hook and lock design has been developed to keep it relevant and valuable to customers. The original design of the perfo back plate used a tapped hole with a small screw, requiring tools, and was significantly more labour intensive.

Chris Jones who has worked at bott for 38 years, gave an insight into how the perfo hooks were made in the 1980’s.

“The method of manufacture has changed over the years. I remember making the back plates for the hooks on a flywheel progression press and then having to tap the M4 thread in each one, one at a time, on a pillar drill with a tapping attachment. This process is now done with a hydraulic machine and the threaded hole has been removed. ”

A small part in a big picture

A small part in a big picture

With growing global concerns about the effect of producing and manufacturing high volumes of waste, industries are beginning to take a step back to gain perspective on the impact that our modern day processes have on the planet. Reaching sustainability in manufacturing requires time, resources and thought, but it is possible to reduce negative environmental impact one step at a time. Not only does focusing on sustainability have positive effects on the environment, but it increases operational efficiency by reducing costs and waste.

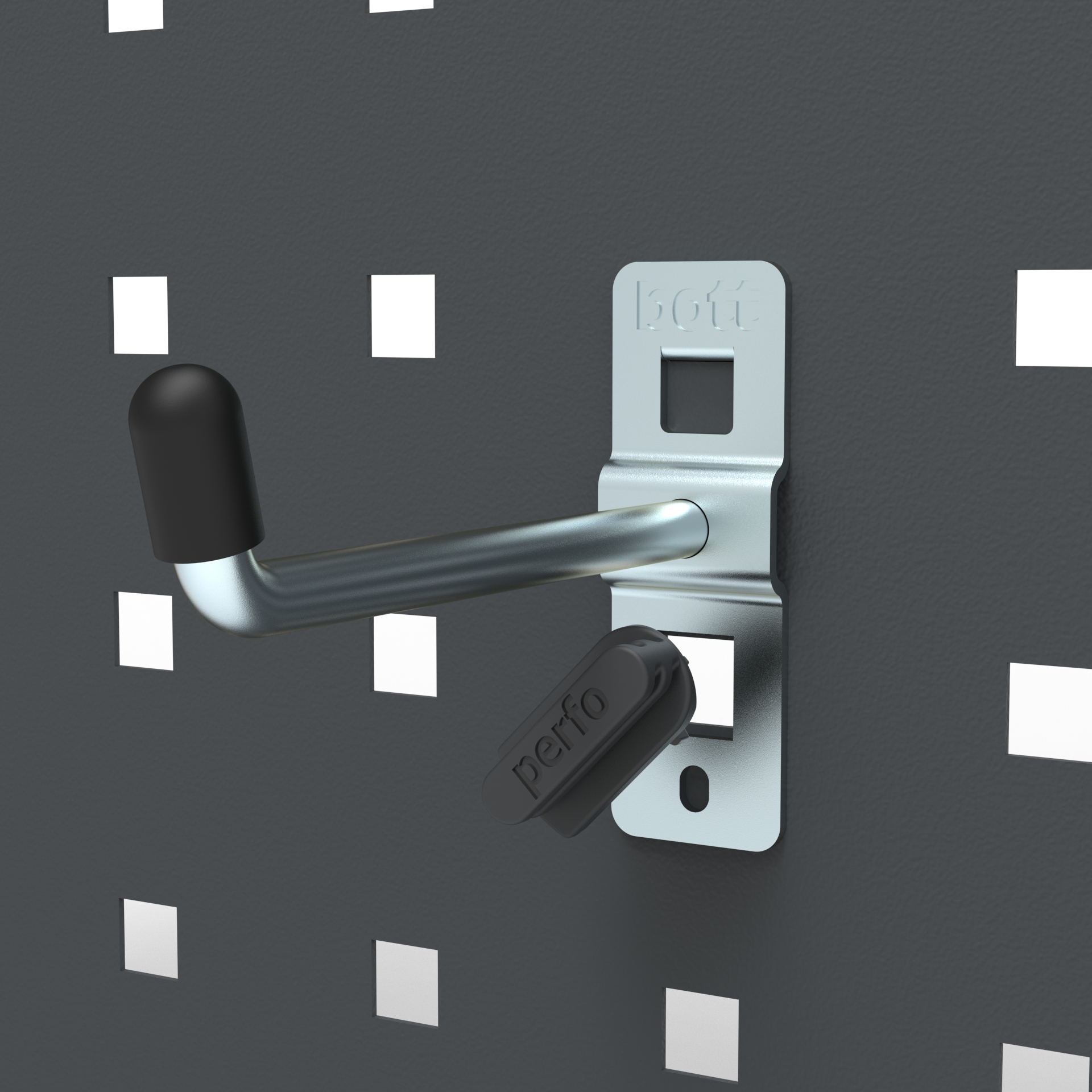

The new perfolock

The new perfolock

It is with this in mind, that our R&D team have designed the new perfolock; made from 100% recycled plastic and is entirely recyclable. Manufactured locally in Barnstaple (approx. 34 miles away) the new perfolock is designed to streamline processes, making it quick and easy to fit, configure and change for developing business requirements. The previous design required a fitting tool (perfolock nylon spanner) to secure the perfolock in the panel, we included one per pack of perfolocks using an average of 306 a week. The new design is fitted by hand, with no need for a fitting tool, not only making it a simpler process, but reducing waste, use of plastic and packaging.

This small piece of plastic may seem insignificant, however since 2010, Bott Ltd has used over 32 million perfolocks! Without this 1cm x 2.5cm part, the foundation of small part storage wouldn’t have unlimited applications in such a wide range of industries and bott would be a different company altogether. We will continue to research and develop new ways to make our products sustainable, aligning with the evolving environmental focus of the world, starting with the small things.