Located in Bolton, Velden Engineering operates out of a site with a rich historical background, dating back to its origins as a cotton mill during the Industrial Revolution. The site, which was once bustling with the production of cotton textiles, illustrates the transition from the traditional textile industry to modern engineering.

Bott Ltd and Velden Engineering share several key similarities as prominent players in the UK's manufacturing and engineering sectors. Similar to bott, Velden excels in providing customised solutions tailored to their client’s specific needs. Emphasising high-quality standards and innovation, they invest in advanced technologies to deliver first-class products and services.

The customer

Velden needed a dedicated area within its factory to centralise production operations, workspace planning, and quality controls. Aimed at revolutionising its manufacturing processes, this ground breaking initiative led to the creation of Velden’s new Industry 4.0 Manufacturing Hub, setting a new benchmark in efficiency and productivity.

Industry 4.0, also known as the Fourth Industrial Revolution, integrates various technological advancements to enhance productivity, flexibility, and competitiveness. Velden designed its state-of-the-art hub as a contained, transparent room with full visibility of its surroundings within the factory, allowing engineers to enter as needed. This ‘clean room’ that is separate from the robust machinery, is a space for cutting-edge technology and IT systems to be maintained in a controlled environment, guaranteeing Velden’s quality and control of products.

The project

With our previous experiences using bott, we were confident in the durability and quality of bott products, knowing they are built to last.

Ray Newton, IT & Systems Manager at Velden Engineering

Velden collaborated with Ceratizit, a high-technology engineering group renowned for its expertise in cutting tools and hard material solutions, for their invaluable advice and expert guidance throughout the project.

Ceratizit identified bott as Velden’s perfect workplace storage solution for this transformative project due to our high standards, superior build quality, and customisable options. Ceratizit also recognised that as a project partner, our innovative and tailored approach to design would ensure Velden’s vision would be perfectly calculated and executed.

A partnership of excellence

Our custom design & build service provided Velden Engineering with a personalised approach to tailor their needs. Forward-thinking project management specialists collaborated closely with Velden, taking the time to visit the site and bring their vision to life. During this hands-on consultation, precise measurements of designated spaces were taken to craft optimal product configurations for the cabinets. Additionally, various worktop samples were showcased, assisting Velden in selecting options that balance durability with style.

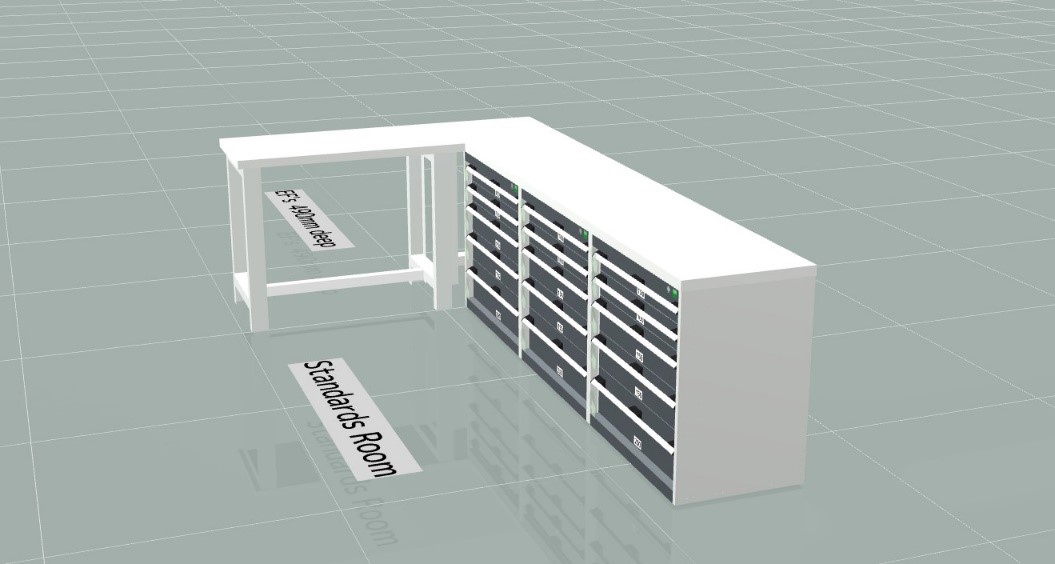

With this free consultation service, our team at bott employed advanced 3D technology to illustrate Velden's vision. We took into account detailed specifications to fit storage around existing structures such as pillars and customised the workbench end frames to avoid interfering with power points.

Unleashing innovation with bott

Velden recognises the immense value of bott's flexibility in accommodating additional requirements to complete their storage solutions.

Customer service from bott was 5 stars throughout the specification process.

A standout feature of the hub is the custom-made hexagon inspection workstation. This bespoke worktop is designed to facilitate three PC inspection points, complemented by three bott cubio mobile tooling cabinets. The worktop was also manufactured with a central channel to feed electrical wiring through a pole, maintaining a clean and professional appearance.

By opting for cubio cabinets, Velden has guaranteed the ultimate professional, heavy-duty storage. Ergonomically designed for the most demanding applications, cubio offers a wide range of sizes and mobile options to fit any workspace. Each cubio drawer cabinet boasts an impressive 1.5 tonne UDL capacity, with 75kg capacity drawers and 100% extension. The central locking system and safety drawer blocking mechanism provides superior security for Velden, upholding their high standards.

At the heart of their operation, this hexagon workstation symbolises the perfect blend of functionality and efficiency that defines Velden’s new hub.

The hexagon highlight

Listening to Velden's operational requirements and unique needs, we were able to craft bespoke ergonomic workstations tailored for optimal comfort and productivity.

For example, specialised workbenches were elevated to accommodate standing work, while custom overhangs on the worktops were installed to facilitate inspection tasks. After thoroughly inspecting the site, thoughtfully placed gaps were strategically integrated into the end frames of the workbenches to avoid obstacles like floor bolts, allowing for additional storage space for computer systems.

Beautifully bespoke

When Velden needed to optimise a compact area within their hub, we rose to the challenge by designing bespoke storage solutions tailored to their needs.

The result? A seamless integration of cubio drawer cabinets, featuring an extended end frame to support an additional worktop. This innovative setup fits perfectly alongside another bench to form a practical L-shaped unit. With our commitment to modular design, customers have the flexibility to customise their products to create the ideal layout for any operation, whilst providing optimal storage.

Modular for maximum convenience

Since the installation of bott solutions, Velden has received an inflow of positive feedback from employees and customers.

A recent LinkedIn post by Velden Engineering about the new setup gathered over 4000 impressions, highlighting engagement and trust in our products. Customer visits have further validated the project’s success, with visitors praising the professional and efficient workspace.

At bott, we also understand that appearance matters when it comes to representing your brand. That's why we offer a choice of colour to align our storage solutions with your brand image and corporate identity. Velden chose an elegant Anthracite grey, ensuring the hub complemented their entire workspace.

Impressions that last

Velden sets exceptionally high standards for the criteria of any workplace project. They could trust bott would meet their demands in terms of build quality, aesthetics, design, fit, and finish. Ray added:

The 10-year guarantee offered by bott was a crucial factor.

At bott, we are dedicated to delivering products that represent a strong, long-term investment. With our in-house design, testing, and manufacturing processes, you can trust in the quality and durability of our products. Our 'built to last' commitment entitles our customers to a 10-year extended guarantee. Proudly UK-manufactured, our support team is just a phone call away. Choose bott for a professional, enduring solution to your storage needs.

Why choose bott?

By embracing the principles of Industry 4.0, Velden Engineering has positioned itself at the forefront of modern manufacturing practices, leveraging advanced technologies to enhance efficiency, flexibility, and competitiveness.

Achieved with the invaluable support of bott and Ceratizit, this project sets a new standard of intelligence within the industry. Together, we have paved the way for a prosperous future for Velden, reinforcing its status as one of the 'best of the best' in the Northwest and ensuring it remains at the cutting edge of engineering excellence.

Manufacturing milestone

Velden was a pleasure to support. Ray had clear goals, and together, we achieved exactly what he had envisaged and I hope to work with him again in the future.

Becky Hicks, Workshop Storage Equipment Project Specialist, bott

Project Service